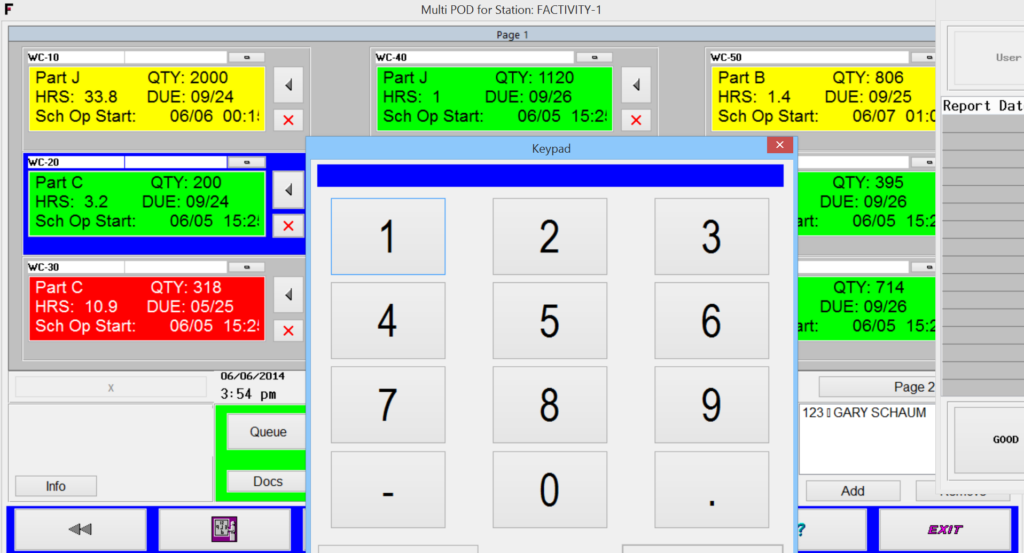

FACTIVITY Improves user interface for operators

Multiple Production Order Documents provide user-friendly touch screen

Cleveland, OH (June 9, 2014) — FACTIVITY has released an enhanced, user friendly interface for its manufacturing software that will help factory operators working on multiple jobs, or with multiple parts, at the same time. The new Multi-POD facility is an improvement on the standard electronic “paperless” operator interface used in the FACTIVITY floor screens. Multi-POD, which stands for Multiple Production Order Documents, allows an operator to interact with an intuitive touch button User Interface (UI) on a single touch screen. FACTIVITY creates a wide range of software solutions for use in manufacturing facilities.

This new user interface provides easy and quick updating to different jobs on different machines all at the same time. “This time saving feature is in line with other lean production processes built into the FACTIVITY product,” said Oskar Schwarz, Senior Consultant, FACTIVITY. “This easy-to-use, one screen per station concept is directly in line with our automation initiatives of seamless integration with the machines on the factory floor.”

In the majority of production environments, a company cannot run production without some operator in attendance. Since the operator cannot be taken out of the picture with regard to floor reporting, it is important to help minimize the interaction with the factory floor MES system and at the same time error proof the process.

“This new product functionality tends to work well in areas on the factory floor that have automation built into the machines,” said John Leibert, President of FACTIVITY. “That is, once the machines are started by the operator, they can continue to run non-stop until all the prepped raw material is consumed.”

In these more automated production environments, the operator, or a set-up employee, will get the machine started by loading control programs and then validate with quality control that the machine is functioning properly as well as making the parts to specifications. Once cleared by quality control, the machine is set into an automation mode and will continue to run. The operator stands by to make sure the finished product is stacked and/or packed properly and that raw material is continually re-loaded.

FACTIVITY Inc. is a technology company providing paperless manufacturing solutions for the factory-floor. FACTIVITY’s Manufacturing Execution System (MES) supports APS Finite Scheduling, Time & Attendance, Shop Floor Management, Machine Monitoring and more. Based in Cleveland, Ohio, the company has served the manufacturing industry for more than 25 years. For more information on FACTIVITY, please visit www.FACTIVITY.com or call 216-514-5141. FACTIVITY™ is provided by and is a trademark of FACTIVITY, Inc.