Advanced Planning and Scheduling Mes Software

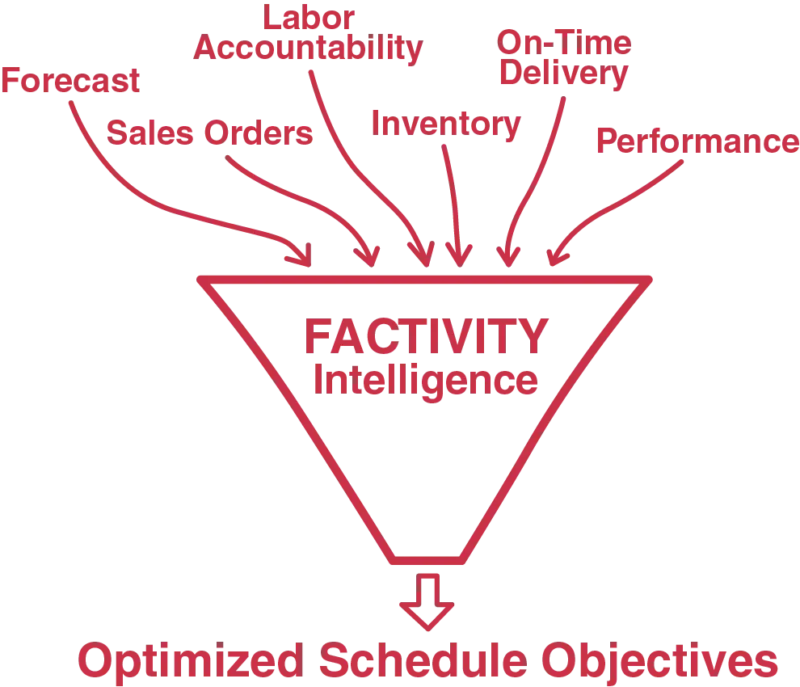

FACTIVITY APS provides manufacturing companies with best of breed in Advanced Planning and Scheduling Software. We provide the information systems to extend your ERP system to the factory floor. Our optimization scheduling logic can evaluate multiple contraints almost instantaneously. It will take into account the best machine from a group, it will consider raw material inventory, as well as, labor and tools. It can evaluate the production schedule based on current inventory levels, current sales order, as well as, from forecasts. The result is visible in both customizable Gantt and spreadsheet format and this realistic achievable schedule can then be “published” electronically to our Shop Floor MES Module.

Get the competitive edge that keeps you in touch with your sales demand

Capacity Planning

- Percentage Utilizationl

- Percentage Availablel

- Hours Available for jobsl

- Any size time-interval

Finite Constraints

- Staff level constraints

- Machine constraints

- Tool constraints

- Material constraints

Machine Effectiveness

- Schedule the best available machines

- Show downtime in the Schedule

- Understand Performance