When it comes to spreadsheets, finite scheduling software or APS, which is best for your manufacturing company?

Take a test and find out

In today’s lean manufacturing environments, many management level executives are realizing that the planning logic provided by their ERP system overloads work centers beyond their capacity and does not reflect the reality of their factory floor. The “infinite” capacity scheduling logic goes back over 60 years and is based on the principles of materials management. It expects a buyer/planner to find a way to level load the production floor, while at the same time taking into account the best practices of customer priorities, grouping logic to minimize set-up and/or BOM considerations of inter-related work orders.

Today, new and younger management teams want a better approach to sequencing work. They are looking for a system that takes into account their actual capacities and limits production (released jobs scheduled to run) without overloading any of the hard asset (machine) resources on the factory floor.

Obviously scheduling more than 24 hours of production on any one asset in a three-shift production facility is not realistic. Yet, many production facilities are forced to accept an often misguided production plan that has been produced for the buyer/planner focused solely on material acquisition. This unfortunate practice is often justified with “this is the way we have always done it.” In the end, it is hurtful to the production floor.

So what do production people do to try to fix this shortfall? They use spreadsheets. I have seen some very thoughtful and creative spreadsheet that serve as the “tech” tool to help produce a more realistic line-up of jobs at each work center, machine, line or cell. Creative yes; sustainable not so much. These Excel sheets take lots of maintenance time (costly) and are usually managed by one person that has all the knowledge (a high risk if they leave the company). Too often changes on the factory floor (customer delivery dates change and/or machines go down) making the use of this low tech approach laborious and impractical.

Finding a better way

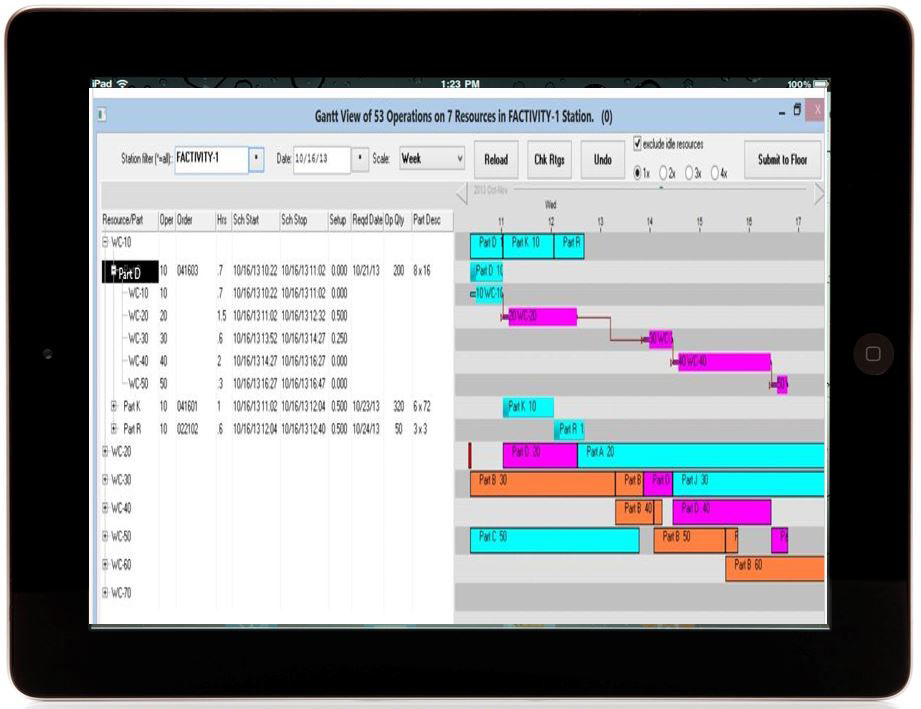

Finite Scheduling software solutions provide job sequencing logic that is a giant step forward from spreadsheet processing. It can take into account changes on demand and shift schedules to reflect overtime and downtime. In addition, a good finite scheduling system will allow some level of “rules” to promote high priority jobs in the sequencing or grouping into families by size, shape, color etc. to minimize set-up and maximize the floor assets. This simple logic is not costly to install and takes little if any time to run. In fact, it can run unattended once it has been custom programmed, with minimal human interaction. The software saves time in producing the schedule, modifying the schedule and laborious production meetings.

So how do you know if a Finite Scheduling System is good for your company? Ask yourself the following questions:

- Does someone in your company spend more than 10 minutes per week working on producing a production schedule?

- Do you spend more than 30 minutes per week in production meetings discussing job priority based on current floor conditions, WIP positions, new customer demands and potential late orders?

- Does your current method of planning involve a system that is capacity “aware” but not capacity “constrained?” That is to say, it is doing little to nothing about capacity management?

- Are you using a spreadsheet to schedule your production?

- Is the value-add part of your business focused on a quality, timely and efficient production processes on the factory floor?

- In contrast to the above, is the value-add part of your business the efficient and effective purchasing of components and sub-assemblies?

If you answered yes to any of the first five questions, then it is time to look into a Finite Scheduling System. And if you answered yes more than once, you need it now.

However, in addition to answering yes to one of the first 5 questions, if your answer to number six is yes, then it might be time to upgrade your software scheduling beyond finite scheduling and to the more powerful (APS) Advanced Planning and Scheduling System. But before you make that decision, you can always validate the need for this advanced scheduling software tool. There are a few prerequisites to making a smart scheduling system decision.

We will define these prerequisites and discuss APS considerations in next month’s issue.