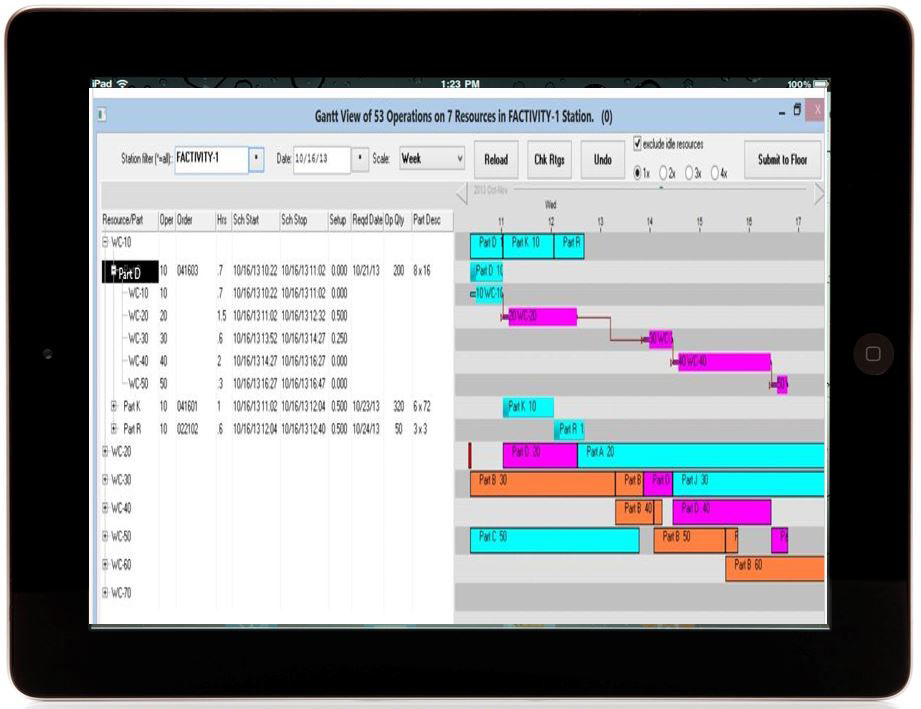

Cleveland, OH (February 5, 2014) — FACTIVITY announces the addition of Gantt chart viewing to the capabilities of its factory floor software. This will enhance production planning for manufacturers as it enables views of all factory floor jobs and expands the capabilities of the Advanced Dispatch List. The Gantt Chart view is now included in FACTIVITY’s Shop Floor Module.

“While a spreadsheet is a grid of data in columns and rows, the Gantt chart is a timeline which visually depicts work over time in graphical horizontal bars which can be dragged and dropped,” said Tim MacCollum, Project Manager, FACTIVITY. “This picture of the shop floor enables a much wider scope of data and a more user friendly scheduling tool.”

The Advanced Dispatch list is a spreadsheet tool that allows schedulers to easily interact with the workload on each machine, and provides a manual drag and drop functionality so jobs can easily be placed into logical sequence. Once the work is sequenced to minimize waste time, the scheduler can immediately reposition the dispatch lists for all the floor assets with the click of a button. This provides the floor with a refreshed list of jobs in the proper order and it can be on-demand.

“Being able to interact with and move jobs on the Gantt Chart allows the user to visually see the impact not only on the operations scheduled for this job, but can also highlight the cascading impact on jobs scheduled in other work centers,” MacCollum said.

To enhance the Advanced Dispatch list and enable employees to see all the operations of a single job and not just the machine components, FACTIVITY has developed an add-on functionality to view the entire routing chain for all released jobs. It has a movable time horizon on the top of the screen and work centers listed down the side in groups defined by reporting stations within the FACTIVITY MES system.

The time horizon can be expanded or contracted to the appropriate view for the scheduler to achieve their objective (longer range or shift based). Jobs can be dragged by operation to an earlier or later time. New schedules are immediately reflected on the FACTIVITY dispatch list for fast reaction to scheduling changes.

“This Gantt is a simpler tool that provides good visibility combined with finite scheduling (level loading) to make this feature a great addition to the paperless dispatching functions in the Shop Floor Workbench,” said John Leibert, President, FACTIVITY.

FACTIVITY Inc. is a technology company providing paperless manufacturing solutions for the factory-floor. FACTIVITY’s Manufacturing Execution System (MES) supports APS Finite Scheduling, Time & Attendance, Shop Floor Management, Machine Monitoring and more. Based in Cleveland, Ohio, the company has served the manufacturing industry for more than 25 years. For more information on FACTIVITY, please visit www.FACTIVITY.com or call 216-514-5141. FACTIVITY™ is provided by and is a trademark of FACTIVITY, Inc.