OEE…does it require machine integration, machine monitoring, both or neither?

Obtaining real-time and real-effective OEE measurements (Part 2) This is the second article in a series on OEE measurements. Read the first article here.

Good Overall Equipment Effectiveness (OEE) systems do not have to include automated feeds from the machines on your floor in order to provide your company with all of the information outlined in Part 1 of this series. And if you decide to capture the data from the machines to feed an OEE system, remember, you will still need a good operator user interface (PC screens) to collect the reason codes and information about the associated operator(s).

Capturing data from machines can cause some misunderstanding between the departments in an organization. Usually, automated data capture is identified by the phrases “machine integration” and “machine monitoring.” Let’s clarify the difference in these two phrases which imply very different project paths with different requirements and different hardware and software.

Machine integration usually means the automation of the machine through a computer control hardware/software combination. This might include specific machine “drivers” and programs to run the equipment. The operator interface is referred to as an HMI (Human Machine Interface) and many times it is customized to your requirements. It is the most expensive approach to automating, if you are primarily interested in capturing OEE from machines.

Machine monitoring does not “control” the machines and does not need parts programs, recipe programs or other software to automate the movement of the machine. It is the least costly automation project. The monitoring equipment is easy to obtain and straight forward to install. The interface equipment can most likely be evaluated on the Internet by your own in-house staff and installed by your own engineering or maintenance department.

The automation from machine monitoring should:

- Capture whether the machine is running or if the machine is down.

- Capture units of production and include production count of pieces, length, weight, etc.

- Track the cycle time or rate of production.

A machine monitoring system can include just the first bullet above and, for an additional cost, you can add on the monitoring specified in bullets two and three.

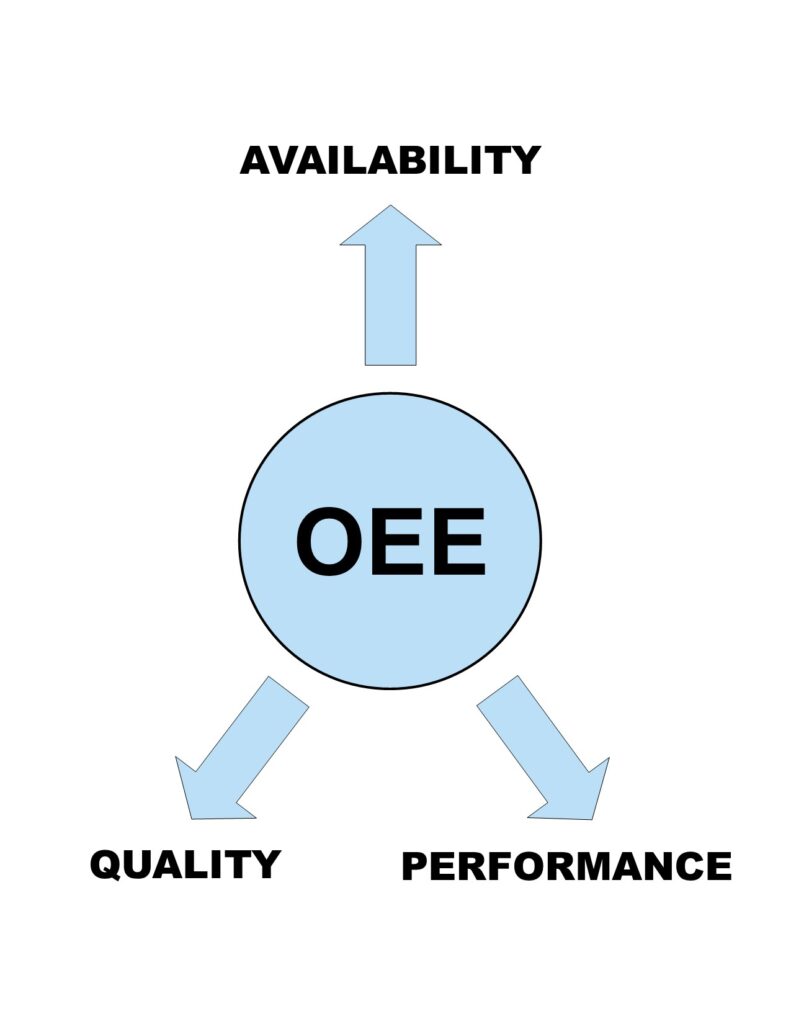

These three machine monitoring automation projects provide some, but not all, of the information for 1) Availability, 2) Quality and 3) Performance respectively. As mentioned above, the other necessary pieces of information will need to be entered by the operator.

Before you get started

Before selecting an OEE system, make sure you see and get a demonstration of the operator interface and make sure that it’s intuitive. That is, what does the operator see on his/her computer screen and how easy is it to interact with the OEE data capture system.

Also, consider implementing an Open Process Control server. These OPC servers are the conduit and data translator when implementing machine monitoring. The OPC server will provide the hub that connects your factory floor equipment through network wires (Ethernet) to a standard Microsoft Windows server. These OPC software packages can interpret the information sent from the machines in the form of “tags” which are from “events” that occur on the machine in real-time. These tags are associated by IP address to a machine (to identify the specific asset) on the floor and then it can be translated into one or more of the measurements for OEE.

One, both, neither?

So back to the title of this article, OEE…does it require machine integration, machine monitoring, both or neither? Machine integration is not a requirement. It is an expensive approach to implementing a complete and useful OEE system. Machine monitoring is less costly and provides automatic capture of some of the OEE measures. It too is not a requirement. However, of the three monitoring projects mentioned above, up/down time (Availability) is usually the place to start.

Both machine integration and machine monitoring together in one project is by far the most costly and most involved and will probably take the longest with little or additional OEE data capture benefit. Neither machine monitoring nor machine integration are required to effectively capture OEE and produce measurements with the caveat that your factory floor will need a good operator interface.