A recent article by a QAD consultant discussed factory floor effectiveness and OEE Metrics. It is a good article, but as a long time MES partner of QAD, I would ask two questions:

A recent article by a QAD consultant discussed factory floor effectiveness and OEE Metrics. It is a good article, but as a long time MES partner of QAD, I would ask two questions:

1. Do You Post Real-Time Production Goals and Factory Floor Metrics?

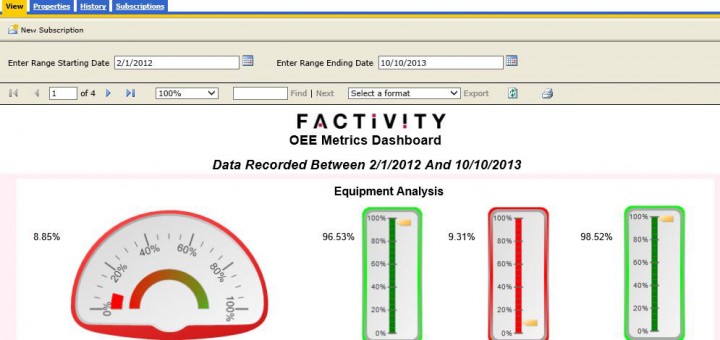

With regard to the manufacturing Metrics on the factory floor, one good place to start is Overall Equipment (and Employee) Effectiveness. Factivity software incorporates OEE as one of several operational metrics provided by our paperless shop floor MES system. This measurement is a combination of three separate and important related measures to help focus on goals relating to performance, quality and availability.

OEE measurements give you real-time data to show if you are on track to meet your goal via displayed dashboard screens, and collect historical data for performance analytics. Up-to-the-minute operations metrics can be helpful to operators and supervisors for immediate correction of the current work in process. In addition, historical operational analytics like in our KPI metrics and Multi-Plant data warehouse provide senior management a way to evaluate areas of concern, such as, too much scrap, unplanned down time and late deliveries.

Producing metrics to assess if you are meeting your goals is ineffective if you are not capturing the factory floor data in real-time. FACTIVITY provides an easy way to allow your operators to work interactively with your jobs and monitor the effectiveness of your employees and your production goals, via our unique, intuitive touch screen approach, which provides a user experience not found in system designs for office and desk workers.

2. Are Work Instructions and Product Specs Visible and in Use at Each Workstation?

Effective manufacturing companies have a focus on timeliness of job completion and lean practices and quality, which means that workers must have immediate access to process instructions, assembly diagrams, specifications and worksheets, as they perform their tasks.

Every workstation should have an easily accessible spot for this necessary paperwork. This fast, efficient delivery of operational specific information comes under the topic of “Paperless MES Systems.” Whether that means no factory floor paperwork, or removing many of the floor documents (and associated handling/distribution), it is the term that comes to mind when discussing availability to work instructions, product specifications, etc.

Factivity provides the delivery of paperless information at the push of a button. This “one-touch” method has proven to be a tremendous help to many operators that use FACTIVITY.

The trick is the make sure the documents are tightly tied to the part being produced. Delivery occurs only after the worker has identified the part and operations step in the routing. Too often, simply putting devices on the floor to deliver documents can be a clumsy kludge of file listing and way too busy for the operators to use. The value in a paperless solution greatly diminishes if floor personnel must locate the correct documents by search through file listings. Make it easy for them, make it error-proof and make it part your factory floor MES decision.