Do You Know Which FACTIVITY Modules Are Right for Your Plant?

At Saint-Gobain improving your factory floor can be a complicated, confusing task. Many executives have no idea which FACTIVITY Modules are needed to accomplish their goals…improving productivity, tracking jobs and employee performance, scheduling jobs, etc.

Factivity has several modules…that accomplish different tasks. Below you will find a brief description of each module. If you want more info, please click on Learn More.

Shop Floor Module

Factivity delivers information to the factory floor in a paperless solution…real-time job documents to operators and supervisors.

As information is collected in FACTIVITY, it is analyzed in real-time, providing appropriate checks, alerts and messages so corrective action can take place.

As a by-product of better floor visibility and control, this floor level system allows effective error proofing of data updating files.

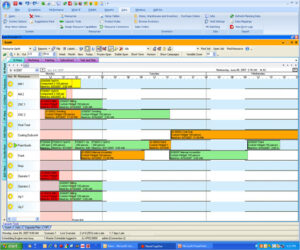

Planning & Scheduling

Provides your production scheduler with powerful graphical interfaces which can be used to visually optimize real-time work loads across work centers and machines.

Provides your production scheduler with powerful graphical interfaces which can be used to visually optimize real-time work loads across work centers and machines.

The interfaces can be optimized with custom filters and advanced planning functions to programatically arrange your work requirements based on your customer criteria and deliver it to the floor.

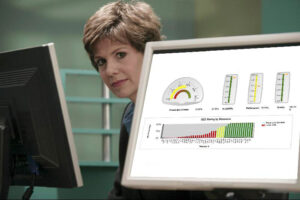

Machine Monitoring Module

Real-time monitoring of floor assets provides the bridge for updating machine status, recording production and enabling visibility to important resources without operator data entry.

Real-time monitoring of floor assets provides the bridge for updating machine status, recording production and enabling visibility to important resources without operator data entry.

Detail events are captured and summarized into such well known metrics as, OEE, with identification to specific assets.