Factory Floor Projects which are targeted to improve the production process on the manufacturing floor come in all shapes and sizes. Part 1 of this series published late last year, started with machine integration considerations and how to improve the understanding of the major components needed in order to communicate electronically directly from factory floor machines into your accounting system. These signal can be translated into production reporting without operator intervention thereby eliminating time and errors often incurred while recording production.

Factory Floor Projects which are targeted to improve the production process on the manufacturing floor come in all shapes and sizes. Part 1 of this series published late last year, started with machine integration considerations and how to improve the understanding of the major components needed in order to communicate electronically directly from factory floor machines into your accounting system. These signal can be translated into production reporting without operator intervention thereby eliminating time and errors often incurred while recording production.

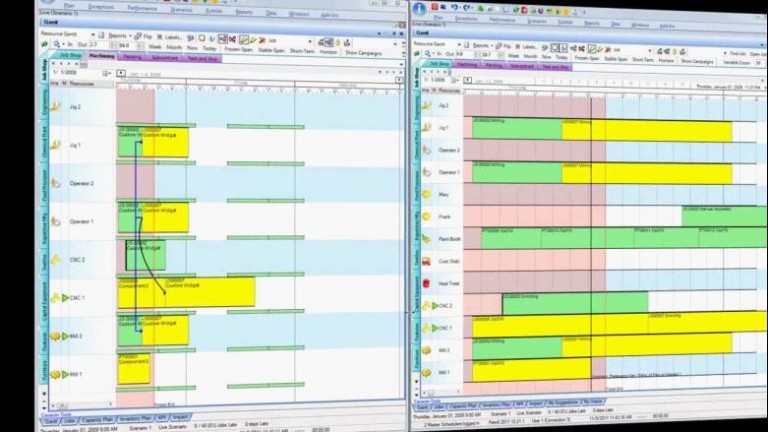

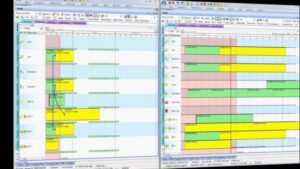

Part 2, published in January, has moved the focused from equipment integration to improving asset (machine effectiveness) through the employment of optimization software and better using a production scheduling process…another misunderstood Factory Floor Project. Specifically, the article discussed the short coming of the most commonly used factory floor planning and scheduling technology…MRP. In use for over a half century, MRP (Materials Requirements Planning) was first used by Black and Decker. Not much has changed in this logic designed to calculate (plan) Material lead-time requirements. In essence this logic is basically using inventory levels and estimate “lead time” to determine material replenishment quantities (purchase orders) as well as estimated completion time of production orders (schedules).

Many things have changed in the last 50 years regarding how manufactures go about planning and scheduling production of pieces/parts/items yet many production facilities still believe that using MRP as a tool to schedule production is appropriate. In this Part 3 we will help define the where and when of using MRP and its next of kin…Advanced Scheduling and Planning (APS). APS should be considered a part of an overall Shop Floor Control implementation project using the latest in software systems functionality found in most Manufacturing Execution Systems MES. For better understand of MES capability follow the link below

http://factivity.com/shop-floor-control-software/

Several things need to be analyze about your business before you can make an all-or-nothing decision about using just MRP or just using APS only; that is exclusively one or the other. Take the following test and see where your company scores on the “need to have APS” scale.

- Evaluate the number of different purchased items …Small = 1 Medium=2 Large=3

- Evaluate the length of time it takes for your production cycle…Long=1 Medium=2 Short=3

- Evaluate the number of operations in your production routing… Large=1 Medium=2 Small=3

- Evaluate if your production process is constrained by labor or tools…Yes=1 No=3

- Evaluate the amount of time for “set-up” or “tear-down”…Long=1 Medium=2 Short=3

Now add you score and see where APS and MRP make the most sense. Low Range is 5-7 or Medium Range is 8-12 or High Range is 13-15

If you are in the High Range then MRP is your best bet to control the multiple purchase items in a short production cycle that has little or no value from optimized sequencing. In this situation, should you feel it advantageous to implement more accurate production order (and operational sequencing) then APS can be used but mostly as a black box to level load the production “to-do” list at each operation or assembly area.

If you fall into the Medium Range then using MRP with APS is probably your best approach. You most likely need a projection of inventory items to be purchased along with lead times and economical purchase quantity breaks which will help the buyers with visibility and maximizing order quantities. MRP provides the functionality. However you most likely still need a short horizon constraint based schedule that helps to minimize the assets associated with scheduling the factory floor. You might be able to get by with a “Black Box” approach (see Part 2 of this series). However there still might be a requirement for the “Value Add” person depending on such external factors as 1) demand changes, 2) customer service issues and/or 3) the need to lean out the production process. In those situations a “Value Add” person might be a good resource to add to the production department.

However, if you fall into the Low Range then you should consider using APS as the system to make most of your production decision. In many case these manufactures have less need for purchase material (item) planning. They general need to focus on the manufacturing process and the complications associated with appropriate sequencing of production orders in an environment that is dynamic. Not just with customer order demand but with constraining the schedule for specific work skills/tools or to work around machines break downs or optimizing parts at an operation to minimize set-ups. And requires a “Value Add” person to maximize the production process.

After making your evaluation and before making an APS decision there are still three critical basic steps that must be taken prior to installing software. These three (3) basic prerequisites must be in place to make a successful APS implementation. These perquisites are as follows:

- A two way integration with the MRP system to allow the APS a method of obtaining part and production information as well as the ability to send back due date changes

- An automated factory floor data collection system, or better yet, MES system that can provide up-to-the-minute updates of floor activities such as production reporting during the shift(s)

- A consultant that not only understands the APS product features/functions but has experience with MRP logic/systems and has knowledge from prior APS/MRP integrations.

FACTIVITY’s Manufacturing Execution Software (MES) collects data from the factory floor and provides metrics needed to implement lean manufacturing practices. The system monitors equipment availability, performance and quality to visually display Overall Equipment Effectiveness (OEE) in real-time and integrates fully with your ERP.